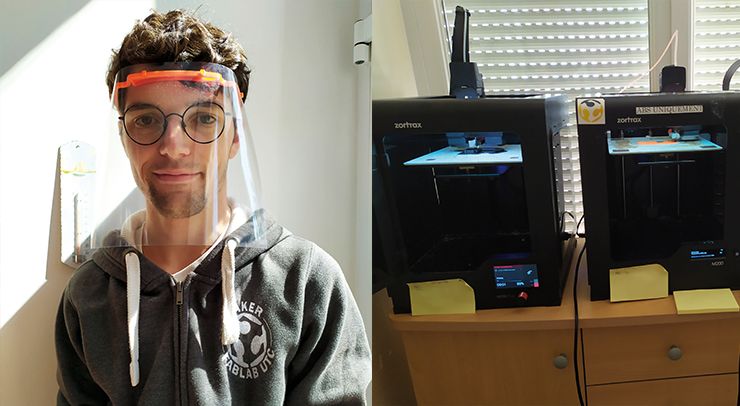

Plastic visors made at the UTC FabLab

Since February 2014, a small space dedicated to prototyping, laser cutting and 3D printing has been located in the heart of the UTC Daniel Thomas Innovation Centre. Its code name? The FabLab UTC. Every day, dozens of students and teachers use it for study purposes or to engage in personal projects.

With the laser cutting machine, our laser printers or the various tools at their disposal, students can to carry out all the projects they want”, explains Justin Darnet, the president of the FabLab association. But on March 12 this year, like all the school buildings, the FabLab closed its doors to comply with the lock-down measures enforced by the Frzench Government. A full halt to the FabLab’s activities. Just a few days after the lock-down began, Justin and his team of volunteers decided to resume their prototyping activities. “We were informed of a call from a national citizen network, “Visière solidaire”. In concrete terms, this appeal encouraged all owners of 3D printers to use them to make visors for health-care workers and professionals exposed to the coronavirus”.

After quick negotiations with UTC’s Administration, the team thus recovered the four printers sleeping in the UTC premises and installed them in Justin’s garage. In just a few clicks, they downloaded the design plans and start to stock up the raw material needed to make the protective face visors. The visor support is produced via a 3D printer and traditional plastic material,” says Justin. You just slide and fix a plastic sheet over it as protection and that’s all there is to it. »

In total, Justin and the other volunteers of the association were able to make several dozen visors. This was enough to provide additional protection for the staff on the front line in managing the crisis. “We’re proud to feel that at our level we can help the health-care workers,” says the president of the FabLab association. “We really encourage everyone who has the resources at home to participate in this effort. »

But beyond the construction of the visors, the small team has other ambitions. “We have been given guidelines to reserve some of our plastic stocks for other projects related to the health crisis, such as the design of mouthpieces for respirators”. The committed student skilfully juggles between his academic obligations and those he has set himself in the fight against the pandemic. “I devote half my time every day to the production of this personal protective equipment, but honestly I feel useful and I don’t see the time going by,” concludes the student. Since the start of the new school year, the 3D printers have returned to the UTC FabLab. From now on, they continue to hum within the walls of the UTC Daniel Thomas innovation centre.