Four UTC undergraduates declared laureates at the 2017 Parrot Award

Intervention in high-risk industrial settings often proves complicated for fire-fighters. Gas, explosive or dangerous products … the emergency services need a maximum amount of information in order to intervene as efficiently and safely as possible. With the objective of making the mission easier, four UTC undergraduates developed a surveillance and alert drone concept that won the PARROT AWARDS 2017.

Night has fallen over an industrial site. The drone is doing the rounds, as usual when suddenly it detects gas and smoke coming from one of the buildings below. It immediately alerts the site supervisor, who call in the fire-brigades who can connect directly to the drone and collect sensor data and analyses onboard camera footage, as they approach the site and prepare their intervention. Less than thirty minutes after the alert signal was issued, the fire is under control and further danger is avoided.

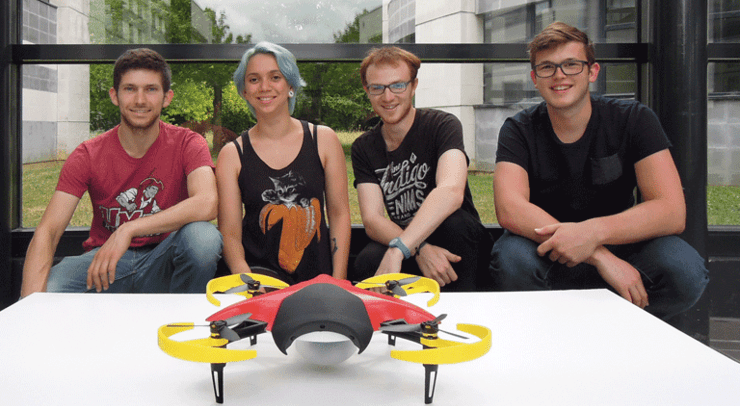

You may think this is just science-fiction? Not for very long now: a prototype alert drone exists already, designed by four UTC undergraduates who, in June, were declared laureates of the Parrot Award 2017. Charles, Romain, Pauline and Alexandre assert that their participation is not due to chance: “We took the opportunity to implement what we had learned in class on a real-life, concrete project, competing with other engineering school teams at an international level”.

The UTC team was supervised by two Parrot designers, but also by the academic staff in charge for the Industrial design specialty (UTC-IDI) and by Thomas Boutin, who head the Prototyping Workshop at UTC. “This year the competition theme was “Drones for Good” and we envisaged several options before we consulted the Compiegne fire-fighters to identify their needs and expectations”, explains Pauline. From these exchanges, the students came up with the idea of an autonomous drone, pre-positioned over a high-risk industrial setting and with the capacity not only to issue an alert signal in case of detected dangers but to continue to exchange with the fire-fighters as they move in. “Our prototype, which we code-named Ray SQ, was a joint construction project between the IDI Design specialist lab and the UTC-Fab-Lab which has a thermoforming machine and a 3D laser printer”, adds Alexandre. “Apart from the propellers, taken from a Parrot model, we assembled and completed the drone from scratch”.

On site, the drone is positioned in a recess, which serves as a storage hangar and recharging point. It takes off regularly and does surveillance patrol rounds. Should an anomaly be detected, the drone contacts the site safety officer over a WIFI link (but the drone is also fitted with a 4G back-up link). The officer then decides whether or not to call in the emergency services who, when they receive this call, can receive the information directly and in real-time from the drone via a specific and very simple “app” and this provides for a much better idea of the situation they will face on site.

Does this suggest we shall soon observe surveillance drones over all factory suites in France? Stay tuned …