Mechatronics, a driving force for cutting-edge technologies

Mechatronics — an alliance of mechanical engineering and electronics – today lies at the core of innovation. It is present in all sectors, leading not only to very ordinary day-to-day objects but also to the building of more complex items such as aircraft, satellites or road vehicles, with a much increased potential. During the Mechatronics REM2016 Conference, which was convened at UTC last June, is a get-together of some of the major actors in this field, and Interactions was fortunate enough to be able to interview the two main proponents, Jamie Paik and Michaël Gauthier, who offered us their vision of mechatronics in coming years.

Mechatronics – a story of synergistic action

Mechatronics can be seen as a synergistic combination of mechanical engineering, electronics, and control theory and computer sciences. It affects design and manufacturing of products for the purpose of optimizing their features, adding new functionalities. It indeed meets a real industrial expectation, connected to our consumer society, increasingly eager as it is to acquire and benefit from technological innovation on an international scale and is to be found everywhere and at the origin of considerable progresses which we can hear about in the media headlines, e.g., driverless cars, to give but one example.

UTC, a key actor to support the cause of mechatronics in France

UTC can muster considerable forces to bolster its reputation in mechatronics and become a privileged partner for a great many industrialists. As of 2008, it set up a collaboration with the CETIM Senlis (acronym for ‘technical centre for mechanical engineering’) to set up an Mechatronics Institute (IM), which is a pole for training, R&D and technology transfer operations; in terms of its training offer, the IM offers several possibilities for UTC students depending on the diploma they are going for, like for instance the MARS specialty (mechatronics, actuators, robotisation and systems) or the specialist Master’s degree SMA (Mechatronic systems and advanced mechanical engineering. Thanks to its Daniel Thomas Innovation Centre, UTC offers prototyping facilities – a key ingredient for mechatronics – which are not only ideally suited to meet the expectations of clients but also is close to entrepreneurial concerns.

Moreover, a special academic Chair was created in 2009, for Hydraulics and Mechatronics, basd on the respective strengths of UTC and the CETIM and enabled a widening of the network of technology-intensive resources in a close relationship with the industrialists. A technological platform, inaugurated in 2014 reinforced the Chair by concentrating the design & modelling tools and the experimental facilities. Through its training for its students and through collective research agreements and activities, UTC offers a high added value of skills and service for both national and international companies, where it can be observed that the needs increase continuously.

One Conference, three events

The Mechatronics REM 2016 Conference enabled the organizers to update the attendees and to present various research results. But in fact, beyond d the single Conference, there were in fact three events: the 11th Franco-Japanese Conference on Mechatronics, the 9th Europe-Asia Conference on Mechatronics and 17th International Conference on REMs (Research and Education in Mechatronics). “The 17th International Conference on REMs initially was the base-line for the two first-named events”, details Michaël Gauthier, Director of the AS2M Department (Control Theory and Micro-Mechatronic Systems) at the FEMTO-ST Institute, Besancon. “It makes lots of sense to combine research and teaching. On a regular basis, the UTC students disseminate the pedagogical contents of their courses in the industrial milieus and that adds a strong leverage effect; knowledge spreads in this manner and it is important to attach high quality to the operations. With new industrial applications, the blend of research and teaching also allow for a technology transfer to the socio-economic world and to Society in general and this proves very efficient way to do this”. “Thirty years ago, very little importance was given to these subjects. Today, we seek to identify interdisciplinary solutions, added Jamie Paik, Director of the Laboratory for Reconfigurable Robotics (RRL), Ecole Polytechnique Fédérale Lausanne (EPFL), Switzerland.

So, can you explain the role for mechatronics today?

Nowadays, you find mechatronics almost everywhere, e.g., in the space sector (satellites …), aeronautics (aircraft stability control …), road vehicles (ESP, ABS …), consumer appliances (washing machines, printers …), or equipment (adapting production means, on line quality assurance and control). “The idea from a day-to-day standpoint, is that physical devices integrate increasing quantities of electronic components, sensors, actuators with a possible interface (EDP or operational) with humans. A symbolic example is the motorcar: 20 years ago, you had an essentially mechanical assembly and the repairs in garages were carried out by mechanics. Now, when you take your car to the garage, they plug it in to an interface and the system diagnoses the problem. Thus we have seen a complete revolution here, where electronics has gradually been integrated — some would say with on-board intelligence, or at least the sensing of information at various mechanical points”, explains Michaël Gauthier. “This is a global trend with less and less purely mechanical parts and we indeed see increasing numbers of connected objects arriving in our lives and environment. We now have to begin working on designs that associate mechanical engineering with control electronics and this calls for highly specific talents and skills, hence the importance of having appropriate courses to have solid enough bases in both fields to assure the synthesis”, he adds.

Some very concrete progress

In their respective laboratories, Jamie Paik and Michaël Gauthier, are developing system that revolutionize our lives and are applicable to numerous sectors. At EPFL, Lausanne, Jamie Paik is focusing mainly on soft robots. “By “soft robots” we are referring to ‘devices’ in silicon or rubber, for example. They are fairly easy to make, there are numerous projects in mechanical or robotic spheres, but it is very difficult to assess the size, the notion of scales is really a problem”, she explains. “One of our applications is a belt with actuators that allow persons with muscular disorders in their abdominal region or legs to regain a degree of mobility thanks to the local additional rigidity offered by the belt. This is important for day-to-day movements, such as the simple climbing or descending of stairs! The technology we use is flexible and it is non-invasive. Now we are seeking to reduce the weight factor and to develop a portable power supply. We are also working on the concept called ‘robogamis’, derived from origamis, a sort of flat 2D robot such as a sheet of paper which will be folded by actuators to form a 3D structure. It is the programming that allows you to control the fold-sequences and to determine how a fold can be transformed. In this area, we have been collaborating notably with Christine Prelle at UTC in regard to the actuators used. For applications in the medical sector, we envision robot sturgeons or uses in satellites, or again for our personal electronics. The power supply still has to be solved before we can assemble truly portable systems,” she adds.

At FEMTO-ST, Michaël Gauthier is working on “micro-mechatronics”, a compression for mechatronics and micro-systems, therefore very small objects. “We design medium-sized (centimetre) robots that can be placed on a table-top, and that will work on (with) very small components at micro or even the nanometric scale: what we call “micro-nano-manipulation”’. We are also investigating very small, highly integrated components for applications in non-invasive surgery. For example, we have developed an active endoscope which allows the surgeon to resect cancerous nodules on our vocal cords. What we have is a complete system lodged in just 2 cm3 with two cameras, two lights, one actuator and a mirror to correct position the laser scalpel. The surgeon traces out on an image the area to be incised and the robot reproduces precisely his hand movements. This system requires lots of work to optimize the design, inasmuch as there is not much room in the operation target ‘field’. So we make robots that assemble small components that can handle both small and extremely small objects”, he adds.

The aim is to make the systems smaller and smarter, but above all else, to be more dexterous when the operations become complex. “In the case of a surgical operation, we want to develop robots that have the capability to move in low-angle areas so as to access certain zones while having more freedom and more mobility. High dexterity is needed for the applications and this can readily be seen in the case of compression applied to human oocytes, knowing that they change properties mechanically as they mature. We then test their mechanical rigidity to see if they are more or less flexible. We have also added some on-board intelligence, since beyond the sensor there is a data processing which leads to a sort of prognosis of the chances of the oocyte being fertilized, as measured “mechanically”. This way we can identify those oocytes ready for fertilization (or, on the contrary, that should be kept on hold. This protocol is tied closely to data processing, we have developed and the classification techniques”.

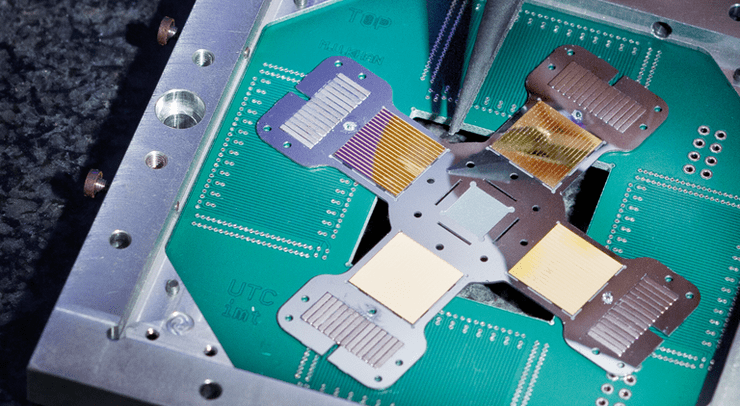

Another application relates to micro-assemblies and it is Michaël Gauthier who works on this theme with the start-up Persipio Robotics, Michaël being one of the co-founders. “What we investigate here (and make) are micro-assemblies, on a purely industrial basis, using small components for the clockwork mechanisms and the microelectronics, with typical dimensions below the millimetre. We also are engaged in work at the nanometric level where there is a blossoming market emerging. We use scanning electron microscopes (SEMs) which can even take us down to the atomic scale [10-8 cm]!” Micromanipulation is used to assemble the parts and are used, for example, to make chemical substance sensors for environmental control and which must have an extremely sensitive measurement capability.

Some ‘revolutions’ that would result from applying mechatronics

“Obviously, there is a wide biomedical scope for applications”, explains Michaël Gauthier, “but there still remains to introduce considerable developments in surgical devices. No doubt in 25 years’ time we shall see operations we simply cannot do today thanks to more flexible, more functional robots. For the time being, surgery depends on the dexterity of the surgeon’s hands, and that has its limits”. Michaël Gauthier also envisions a revolution in pharmaceuticals: “We shall see a complete substitution for chemical based medicinal drugs by biological compounds. That is to say, that we shall longer be dependent on drugs (in its wider connotation) but rather on cells that act in a medicinal way. Knowing that cells have a dimension of only several tens of microns, the action of isolating them and growing them is part of possibilities for micro-robotics”. In like manner he foresees progress being made in the industrial world. “There is a huge need for further miniaturization of lots of components! Take the example of mobile phones. They have grown in size over recent years. They integrate more and more functions and the components are decreasing in size. Their assembly calls for lots of operations on these complex systems and they cannot be done either than by hand for the time being. We do not have alternate solutions for this! We often tended to think that everything was robotized, but bit is simply because we are at the limits to manual manipulations. All the more so that that when you pick up an object there” is a natural human tremble of some 50 microns we can hardly detect. But, consequently, we cannot handle objects at that scale and to do so we need robots that work under microscopes. With the ongoing micro-robotics revolution, we shall be using a position to clear this obstacle and the market ahead will grow huge. I also see a snowballing effect — robot production will make their assembly easier. Having said this, the systems too will be designed accordingly and the market for these micro-robots will surely explode. As I see it, there will be a joint growth between product and robot developments. We have, in a sense, broken an earlier logic. There was no technology previously, so no market. We then crated the technology and the market followed suit. We saw something similar in the history of computers – there was a time only years ago, when we did not know how we were going to use them. Today, every home has one and likewise at our work-desks”.

For Michaël Gauthier, there is an even more futuristic vision: that of 3D printing – which already exists but which soon will enable us to create and “print” modulated, connected objects, with the electronics needed installed during the print process “This will no doubt occur in the Main Street market where people will be able to print their goods directly, as and when needed”. Finally, the future will no doubt have strong ties with the space sector industries, where the advantage of micro-robotics will lie in decreased weight and component size (weight being a key factor to, the cost of launching the devices into space).