These theses that change life: Mechanical failure

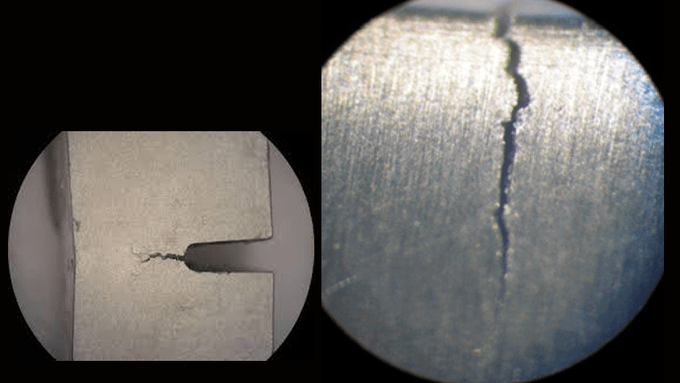

A mechanical failure is often the result of a material fatigue. The natural ageing of parts, notably those made from metals and alloys, leads to the formations of cracks that may propagate and cause the part to break. And because this may have serious consequences, it is important to understand how cracks form ad evolve in time.

Following a “4 week Erasmus stay that finally lasted 4 years”, Chrysanthi Papamichail, with her engineering diploma from the Ecole Polytechnique in Athens (graduated in electrical engineering and computer science) and a Master’s degree in applied mathematics is the author of a thesis on catastrophic mechanical failure she defended at the UTC-LMAC Laboratory in a collaborative programme with the UTC-Roberval Laboratory. The thesis subject she chose was the “Estimation of dynamic systems with applications in mechanical engineering sciences”.

As Chrysanthi detailed for us, “we associate stochastics processes with digital techniques to model a crack and determine its propagation characteristics”. By applying a mathematical formula, the random phenomenon can be recreated virtually. “The equations enable us to estimate the propagation of the cracks over a set time interval, to identify the moment of catastrophic failure (i.e., rupture) and thus to propose an operational life expectancy for materials”. The results obtained then allow us to make comparisons with real data and to improve the algorithm and also to concomitantly reduce the resource needs in terms of computational power.

There are some important applications areas, in numerous fields: “My equation is sufficiently reliable and powerful per se to be used in any sector that employs metal parts that could prove dangerous. The range of possible applications runs from building construction to aerospace, from railroads to health concerns about implants. But it can also be applied to natural events such as earthquakes or biological phenomena”, she details.

For the time being, the accent is on applications in aerospace where accidents can lead to death. Nuclear power production also is an area where there have been significant progress, for reasons you can well imagine “but only a few countries are concerned and the data is often shrouded in secrecy” adds Chrysanthi.