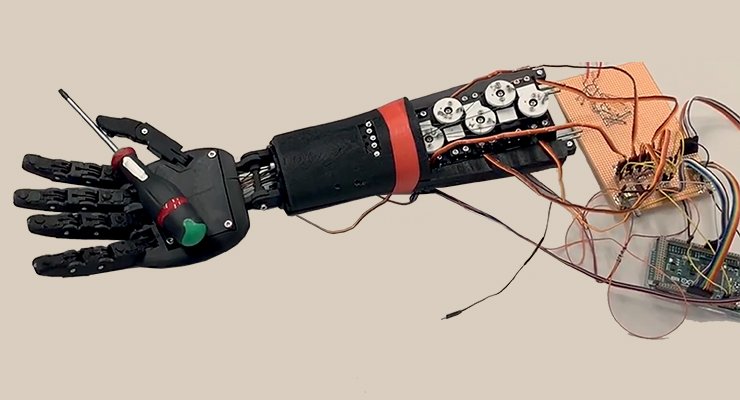

TN25 gets to grips with biomechatronics

From design to manufacture, the biomechanical hand prototyped at UTC is the concrete expression of the new TN25 CC project, at the end of the Integrated Mechanical Design course (bac+5), for an experimental and mechatronic implementation of the skills acquired in various courses.

Reproducing the functionalities of a hand and its complex system of movements using mechatronics — a synergistic and systemic combination of mechanics, electronics, automatic control and information technology — is the confrontation with a real case in a constrained environment undertaken during a semester (from September to January) by two groups of seven students supervised by seven research scientists and engineers from UTC* specialising in mechanics, electronics, manufacturing systems, sensors, signal processing and control. “This is the first time that we have offered this CC course, which is linked to technological developments and the identification of new needs and skills acquisition by the companies with which we have partnerships,» stresses Laurent Petit, lecturer at the UTC, who supervised the project with Hani Al-Hajjar, also a lecturer at UTC. The prototyping and experimental aspects characterise this CC, which is an extension of the work carried out by the lecturer-research scientists on the study of micro-mechatronic and micro-robotic systems. This implies real interactions. The aim was to interest students in the design of complex systems and to make them aware of the integration of functions in a collaborative and experimental implementation».

From simulation to application

The biomechanical hand was an imposed challenge that required «reflection on the functional complexity of a hand and its movements», explains Hani Al-Hajjar. The two groups came up with two different solutions, one of which incorporated more actuators in order to translate gestures more accurately. “The challenge was to accommodate a multitude of components in a small space. How do you arrange them so that they don’t affect the function to be performed? How do you manage the connections so that they don’t interfere with movement? How do you integrate temperature and pressure sensors at the fingertips to detect and squeeze an object and identify the presence of a heat source to prevent degradation? Producing a prototype means understanding situations and aspects that cannot be simulated, managing a project in real time and reviewing the design to meet requirements. «We weren’t looking for innovation, but for a way to take into account the integration of technologies and functions, to become aware of the feasibility of the project within a given timeframe, with the resources available, in particular the 3D printer specifically acquired by the UTC to manufacture the parts that the students would need. That’s what our teaching method is all about», explains Hani Al-Hajjar. A second session of the UV TN25 is planned for the start of the new academic year, especially as the enthusiasm of the students for the application of their skills is fuelling the prospects. The biomechanical hand could be used in other courses as a case study for systems design and simulation.

* including Muneeb Khan, research engineer in charge of the micromechatronics platform at UTC’s Roberval laboratory, Erwan Dupont, lecturer-research scientist in the Mechanical Engineering department and working at UTC’s Roberval laboratory, Christine Prelle, professor in Mechanical Systems Engineering at UTC’s Roberval laboratory, Nicolas Piton, head of the UTC Fablab and Frédéric Lamarque, Director of Research, UTC.